Extraction

Alberta's bitumen — a rich, carbon-heavy component of heavy oil — contains asphaltenes. These are extracted using heat and chemical processes, isolating the carbon-rich material needed for fibre production.

Unyielding. Unmatched. Unapologetically Advanced.

Materials matter in the pursuit of progress. Carbon fibre isn't just strong; it's transformative. Engineered at the molecular level, this material redefines what's possible in mobility, energy, and infrastructure.

Born from precision and powered by innovation, carbon fibre offers a strength-to-weight ratio that outperforms steel, yet its versatility has a purpose across industries and sectors. It's the backbone of next-generation vehicles, the silent force behind wind turbines, and the trusted ally in aerospace, pipelines and fuel cells. Its applications are endless; at the right price.

At Alberta Innovates, we don't just see carbon fibre as a material — we see it as a catalyst. A conduit for cleaner energy, smarter design and resilient systems. It's where science meets sustainability, and where Alberta's ingenuity takes flight.

“Carbon fibre isn't the future. It's now. And it's ours to shape.”

Alberta's bitumen — a rich, carbon-heavy component of heavy oil — contains asphaltenes. These are extracted using heat and chemical processes, isolating the carbon-rich material needed for fibre production.

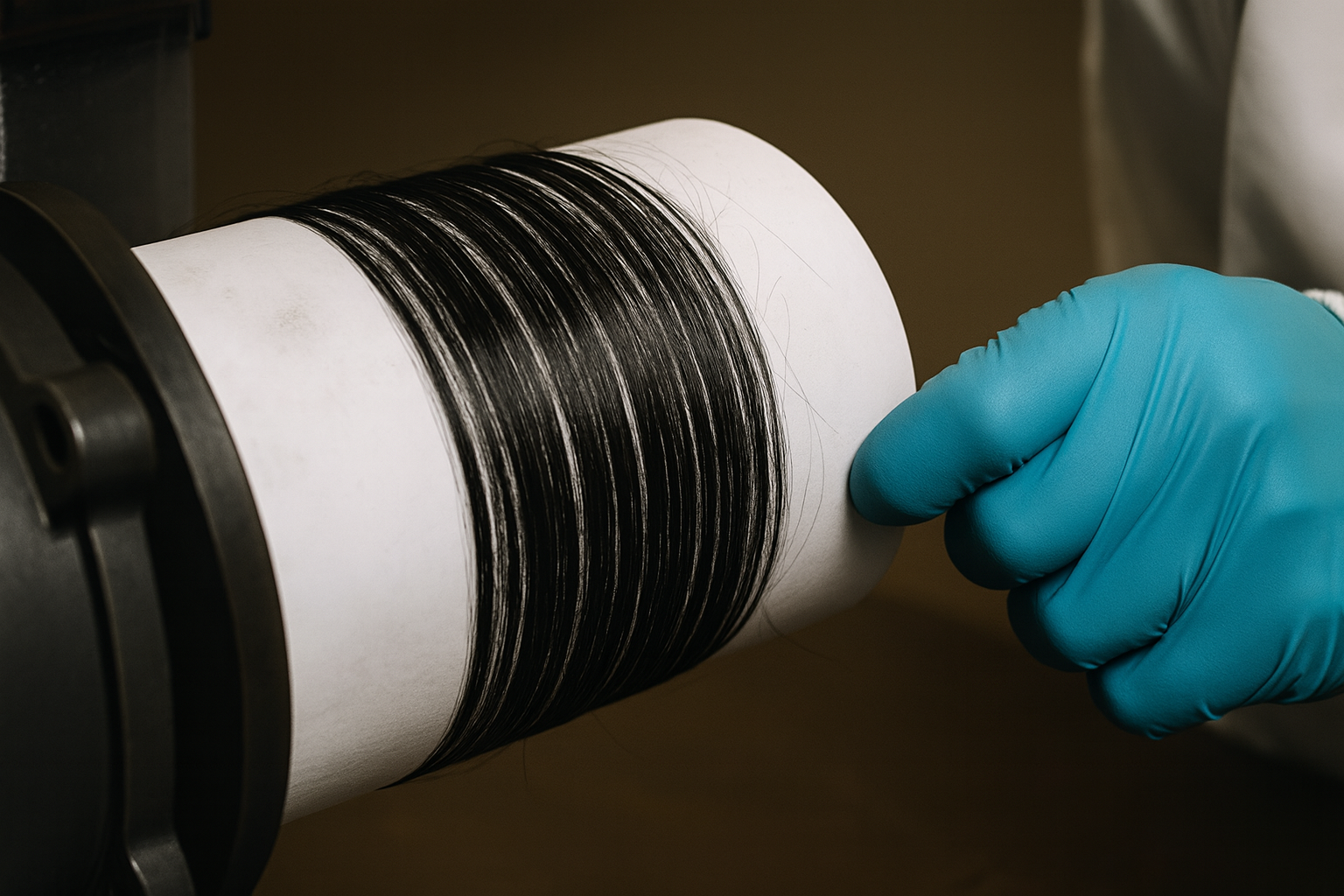

Through melt spinning, the extracted asphaltenes are heated and extruded into long, continuous fibres. This transformation marks the beginning of a new carbon fibre — one that's engineered for strength and versatility.

Oxygen is introduced to the fibres, enhancing their structural integrity and preparing them for the final stage. This step ensures the fibres can withstand the intense conditions of carbonization.

The stabilized fibres are heated to temperatures approaching 3000°C. This process converts them into pure carbon fibre — a material prized across industries for its unmatched strength-to-weight ratio and durability.

Reimagining Resources. Repositioning Alberta.

By diverting bitumen from combustion to high-value, non-combustion applications, Alberta is reducing emissions and increasing the economic return on each barrel.

Producing carbon fibre from bitumen generates significantly fewer greenhouse gases compared to traditional feedstocks.

Carbon fibre is up to five times stronger and five times lighter than steel. It's essential to industries that drive modern economies — from aerospace and defence to automotive to renewable energy and medical technologies.

Located in Edmonton, this is the country’s first pre-commercial scale, industry accessible carbon fibre research facility. It positions Alberta as a leader in advanced materials and clean technology.

At the intersection of innovation and industry, Alberta is home to Canada's first pre-commercial-scale, industry-accessible carbon fibre production facility. This isn't just a new chapter for materials science — it's a shift in how we think about our resources.

Carbon fibre is the material of the future, and Alberta is leading the way in how it's made. With the launch of Canada’s first pre-commercial scale, industry-accessible carbon fibre research facility in Edmonton, Alberta, the province is transforming its bitumen into advanced materials.

Carbon fibre from bitumen isn't just about innovation. It's about redefining the role of bitumen in a low-carbon economy. This facility is turning a familiar resource into a high-performance advanced material that could transform industries, positioning Alberta at the centre of the low-carbon economy.

Join us in transforming Alberta's resources into the materials of tomorrow.